Safety Considerations When Working on Watch Movements and Repairs

60 Second Summary

Watch repair safety is crucial when working with delicate mechanical timepieces. Proper movement handling, correct tool use, and essential precautions protect both you and your valuable watch components. From eye protection to static electricity prevention, following proven maintenance protocols ensures successful repairs without damage. Personal safety measures include wearing protective gear, maintaining clean workspaces, and using proper lighting. Watch safety involves careful movement handling, temperature control, and magnetism prevention.

Working with mechanical watch movements requires precision, patience, and most importantly, proper safety protocols. A single mistake can damage expensive components or, worse, cause personal injury. The good news? Following basic watch repair safety guidelines protects both you and your timepiece investment.

Modern movement handling techniques have evolved significantly since the early days of watchmaking. Today's DIY enthusiasts have access to better tools, clearer guides, and comprehensive safety information that makes home watch assembly both achievable and safe.

7 Most Common Mistakes When Using Watch Repair Tools

1. Ignoring Respiratory Precautions with Cleaning Solvents

Watch cleaning requires solvents and lubricants that can be harmful when inhaled. Many DIY enthusiasts work in poorly ventilated spaces without realizing the health risks. Even "safe" cleaning products can cause respiratory irritation with prolonged exposure.

Modern watch oils and cleaning fluids are much safer than older formulations, but precautions remain essential. Working in a basement or closed room without proper ventilation amplifies these risks significantly.

How to Avoid This

Work in well-ventilated areas or outdoors when possible. Use a small fan to improve air circulation around your workspace. Keep cleaning solvents in sealed containers when not in use. Consider wearing a basic dust mask if you're sensitive to chemical odors. Take regular breaks to get fresh air, especially during longer maintenance sessions.

2. Poor Hand Protection Leading to Component Damage

Bare hands transfer oils, moisture, and debris to delicate watch components. Fingerprints on movement plates can cause corrosion over time. Skin oils interfere with proper lubrication and can attract dust particles that damage moving parts.

Many beginners feel they need direct finger contact for better dexterity. However, this approach often leads to dropped components, contaminated surfaces, and compromised movement handling precision.

How to Avoid This

Always wear gloves when handling watch components. The gloves included in Rotate's watchmaking kits provide excellent dexterity while protecting components. Keep your hands clean and dry before putting on gloves. Replace gloves if they become contaminated or torn. Use tweezers instead of fingers whenever possible for component manipulation.

3. Creating Unsafe Work Environments

A cluttered workspace leads to lost components, accidents, and frustration. Poor lighting causes eye strain and makes precision work nearly impossible. Working on unstable surfaces introduces vibrations that can damage delicate components.

Temperature extremes affect both your comfort and component behavior. Hot environments cause metals to expand, while cold conditions make oils viscous and difficult to work with.

How to Avoid This

Set up a dedicated workspace with stable surfaces and excellent lighting. Use the organizing cases included with movement kits to keep components sorted. Maintain a comfortable room temperature between 68-72°F. Keep your workspace clean and free from distractions. Store tools properly when not in use to prevent damage and loss.

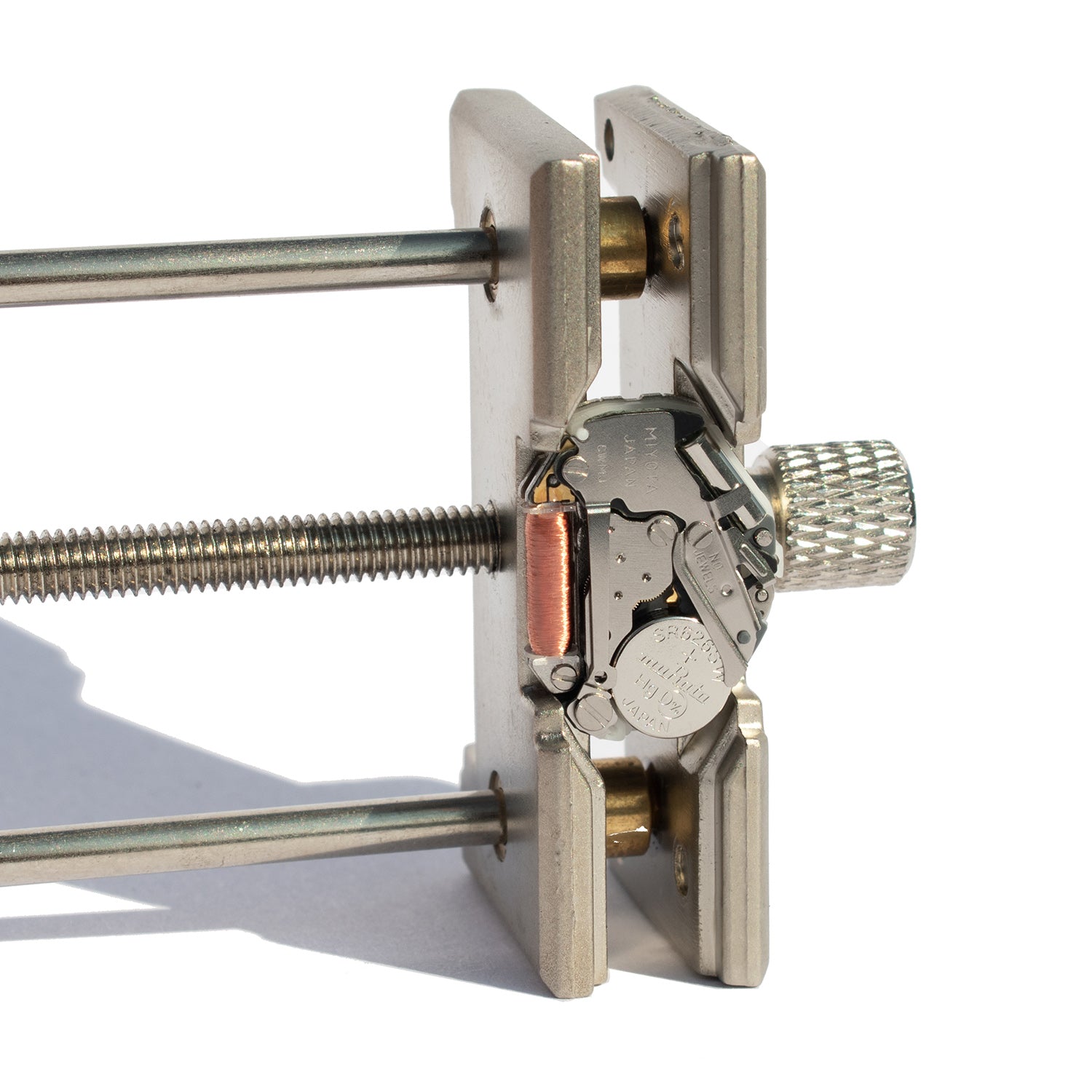

4. Improper Movement Handling Techniques

Dropping a movement can destroy hours of careful assembly work instantly. Applying excessive force when components don't fit properly often indicates alignment issues, not the need for more pressure. Rushing through delicate operations leads to bent components and damaged threads.

Many beginners struggle with the transition from everyday tool use to precision movement handling. Watch components require gentle, controlled movements rather than the forceful approaches used in other repair activities.

How to Avoid This

Support movements properly using a movement holder during assembly. Apply gentle, steady pressure rather than sudden force. If components don't fit easily, stop and check alignment before proceeding. Practice basic techniques on less valuable movements before working on expensive pieces. Follow the step-by-step guides included with Rotate's kits carefully.

5. Using Wrong Cleaning Methods and Lubricants

Using household cleaners or inappropriate solvents can damage movement components permanently. Too much lubricant attracts dirt and interferes with proper function. Wrong lubricant types cause increased wear and timing problems.

Different movement components require specific lubricants applied in precise quantities. The "more is better" approach doesn't work with watch lubrication.

How to Avoid This

Use only watch-specific cleaning products and lubricants. Apply lubricants sparingly using proper application tools. Clean components thoroughly before applying new lubricants. Follow manufacturer recommendations for lubricant types and quantities. When in doubt, less lubricant is usually better than too much.

6. Ignoring Water Resistance Precautions

Improper gasket installation compromises water resistance completely. Using incorrect tools to install case backs can damage threads and sealing surfaces. Many DIY enthusiasts don't understand that water resistance requires perfect sealing at multiple points.

Testing water resistance requires specialized equipment that most home workshops lack. Assuming your assembly is water-resistant without proper testing can lead to expensive water damage.

How to Avoid This

Replace gaskets with new ones included in your watchmaking kit. Install case backs evenly and gradually to avoid cross-threading. Don't over-tighten, which can damage threads or compress gaskets excessively. Consider your assembled watch splash-resistant only unless professionally tested. Avoid swimming or showering with newly assembled watches until proper testing confirms water resistance.

7. Working Beyond Skill Level Without Proper Knowledge

Attempting complex repairs without adequate knowledge leads to expensive mistakes. Skipping fundamental techniques to rush toward advanced projects often results in damaged components. Not recognizing when to stop can turn minor issues into major problems.

Building skills gradually ensures better results and reduces the risk of costly errors. Understanding watch anatomy provides the foundation for safe, successful repairs.

How to Avoid This

Take advantage of Rotate's comprehensive guides and support resources. Practice basic techniques thoroughly before moving to advanced procedures. Build your tool collection gradually as your skills develop. Connect with the watchmaking community for advice and troubleshooting help.

Time isn't just measured, it's built with your own hands.

Start your watch repair safety journey with Rotate Watches, where complete DIY kits transform curiosity into craftsmanship.

Browse our collection to find your perfect match, from complete watch kits to intricate movement kits.

Your watchmaking story begins with proper safety. Start building today.

FAQ

Q. What essential safety gear do I need for watch repair safety?

You need safety glasses, gloves, good lighting, and a stable workspace. Gloves protect components from skin oils while safety glasses prevent eye injuries from flying springs during movement handling.

Q. How can I prevent static electricity damage during tool use?

Use anti-static work surfaces, touch grounded metal objects before handling components, avoid synthetic clothing, and work slowly to minimize friction. Maintain proper humidity levels in your workspace.

Q. What's the biggest mistake beginners make with movement handling?

Applying excessive force when components don't fit properly. Watch parts require gentle, precise movements. If something doesn't fit easily, check alignment and technique rather than using more force.

Q. Are precautions different for mechanical versus quartz movements?

Yes, quartz movements require extra static electricity protection due to electronic components. Mechanical movements need careful spring tension handling and proper lubrication precautions during maintenance.

Q. How do I know if my workspace is safe for watch repairs?

Check for stable surfaces, excellent lighting, comfortable temperature, minimal magnetism sources, good ventilation, and organized tool storage. Keep the area clean and free from distractions.

Q. What should I do if I damage a component during assembly?

Stop immediately, assess the damage, and contact Rotate's support team for guidance. Many kits include warranty coverage for damaged parts. Don't attempt to continue with damaged components.