Most Common Mistakes When Using Watch Repair Tools and How to Avoid Them

60-Second Summary

Watch tool mistakes can turn a simple repair into an expensive disaster. From over-tightening screws to using wrong batteries, these repair errors plague both beginners and experienced enthusiasts. Common tool misuse includes forcing movements, neglecting gasket care, and attempting complex repairs without proper knowledge. Watchmaker tips emphasize gentle handling, using correct tools for specific tasks, and understanding your timepiece before making adjustments. Proper maintenance involves regular cleaning, appropriate storage, and knowing when DIY efforts should stop. Whether you're working with Seiko NH36 movements or building complete timepieces with watchmaking kits, avoiding these mistakes saves time, money, and preserves your watch's functionality.

Building and maintaining timepieces requires precision and patience. Yet countless enthusiasts make preventable watch tool mistakes that damage their prized timepieces. Whether you're assembling your first DIY watchmaking kit or maintaining a vintage collection, understanding common repair errors protects your investment and ensures successful outcomes.

Modern watchmaking has become more accessible thanks to companies like Rotate Watches, which provide complete watchmaking kits starting at $140. However, accessibility doesn't eliminate the need for proper technique and knowledge.

Most Common Mistakes When Using Watch Repair Tools

The difference between successful watch repair and costly damage often comes down to technique and tool selection. Understanding movement types helps prevent tool misuse and ensures appropriate care for your specific timepiece.

Quartz vs. Mechanical Movements require different approaches entirely. Quartz movements use electronic circuits and batteries, making them sensitive to static electricity and moisture. Japanese quartz movements offer reliable timekeeping but need careful battery replacement procedures.

Mechanical movements, whether found in Seiko watch movements or premium Swiss calibers, depend on springs, gears, and escapements. These intricate systems require different tools and handling techniques than their electronic counterparts.

Hand-wound vs. automatic mechanisms present unique challenges. Hand-wound movements like the Seagull ST3600 need careful winding to avoid spring damage. Automatic movements such as the NH36 include rotors that can be damaged through improper handling.

Understanding how automatic watches work prevents common mistakes when servicing these complex mechanisms. Each movement type has specific tolerances and requirements that must be respected during repair procedures.

1. Over-Tightening Screws and Components

Watch tool mistakes often begin with excessive force application. Screws in timepieces are typically made from soft metals like brass or steel, designed for precision rather than strength. Over-tightening strips threads, cracks components, and can completely destroy delicate parts.

Case back screws, crown screws, and movement screws all have specific torque requirements. Most watch screws need only finger-tight pressure plus a quarter turn. Using power tools or applying excessive force with screwdrivers creates irreversible damage.

The delicate nature of watch anatomy means that even small mistakes can cascade into major problems. A stripped screw hole might require case replacement, turning a simple repair into an expensive reconstruction.

How to Avoid This

Use proper-sized screwdrivers that fit screw slots perfectly. Watchmaker tips emphasize starting screws by hand to ensure proper thread engagement. Apply gentle, consistent pressure rather than forcing components together.

Quality watchmaking kits include precision screwdrivers designed for delicate work. Practice on spare components before working on valuable timepieces to develop proper feel and technique.

2. Using Incorrect Tools for Specific Tasks

Tool misuse represents one of the most common repair errors in amateur watchmaking. Using kitchen knives as case openers, pliers instead of proper hand pullers, or incorrect screwdriver sizes damages components and creates safety hazards.

Each watchmaking task requires specific tools designed for that purpose. Case opening requires proper case knives or specialized openers. Hand removal needs dedicated pulling tools that grip without applying excessive pressure to delicate components.

Swiss movement vs Japanese movement construction often requires different tool approaches. Swiss watches might use different screw types or case construction methods than Japanese timepieces.

How to Avoid This

Invest in proper tools rather than improvising with household items. Complete watchmaking tool sets provide everything needed for basic repairs and maintenance procedures.

Study tool usage before attempting repairs. Understanding proper technique prevents damage and ensures successful outcomes. Maintenance procedures should always use appropriate, clean tools designed specifically for watchmaking applications.

3. Neglecting Proper Cleaning and Preparation

Watch tool mistakes often stem from working in dirty environments or using contaminated tools. Dust, oils, and debris can enter movements during repair, causing timing issues and component wear that might not appear until months later.

Proper workspace preparation includes clean surfaces, adequate lighting, and organized tool storage. Contaminated tools transfer dirt and oils into delicate mechanisms, creating long-term reliability problems that are difficult to diagnose later.

Skeleton watch maintenance becomes particularly important since open dials expose movements to environmental contaminants. Regular cleaning prevents buildup that can affect performance and longevity.

How to Avoid This

Clean tools before each use with appropriate solvents. Maintain organized workspaces free from dust and debris. Use proper cleaning techniques designed specifically for watch components.

Work in well-lit areas with proper magnification when needed. Loupe magnifiers help identify small problems before they become major issues requiring extensive repairs.

4. Ignoring Movement-Specific Requirements

Different movements have unique characteristics that affect repair procedures. Repair errors often occur when treating all movements identically rather than understanding specific requirements for each caliber type.

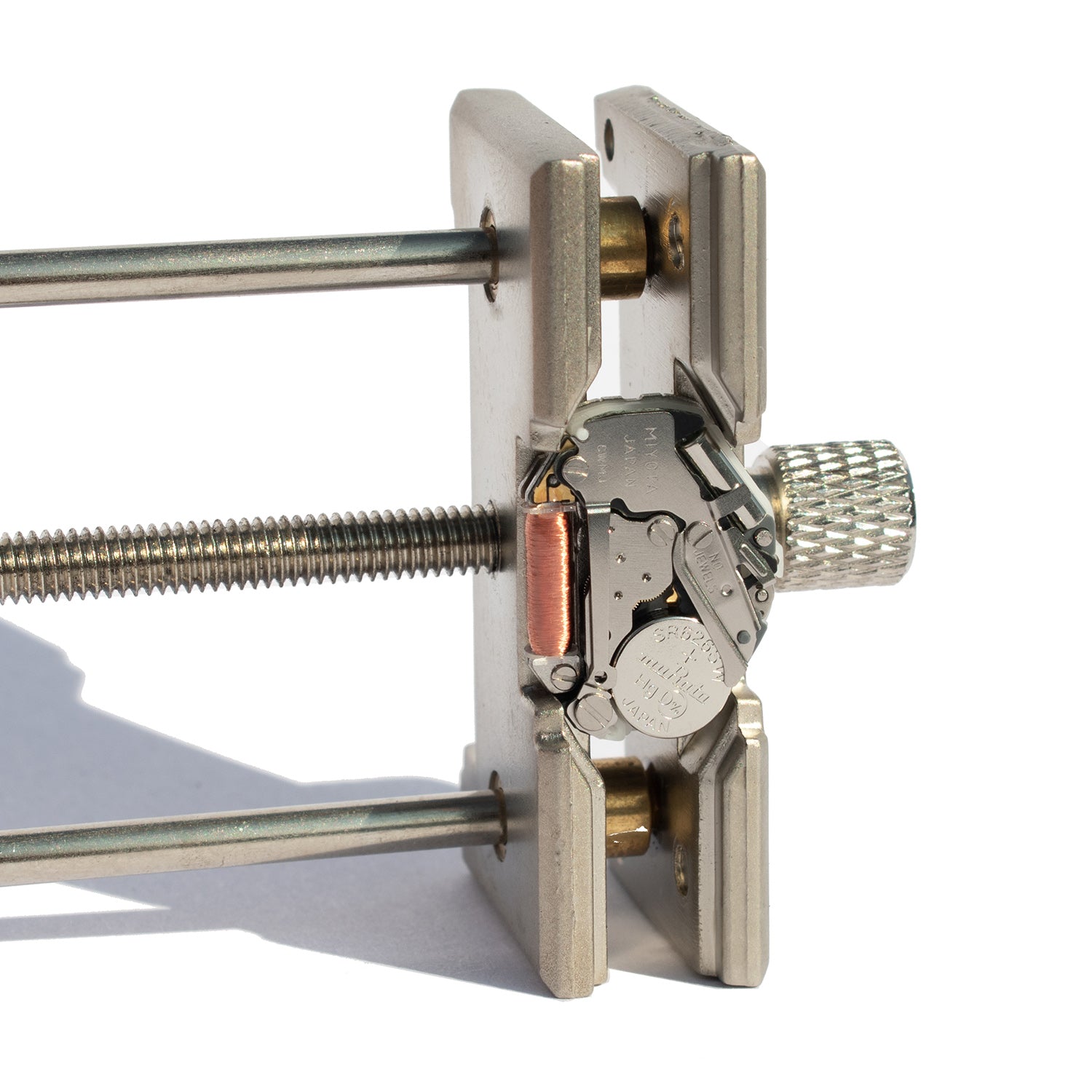

Miyota movements might have different hand-setting procedures than Seiko calibers. Understanding these differences prevents damage during routine maintenance and adjustment procedures.

Seiko movement accuracy depends on proper regulation and adjustment techniques specific to each caliber. Generic approaches often fail to achieve optimal performance from these precise mechanisms.

How to Avoid This

Research specific movement characteristics before beginning work. Understand mechanical watch basics for your particular caliber type and model.

Consult movement-specific guides and documentation. Watchmaker tips emphasize understanding your timepiece thoroughly before attempting any adjustments or repairs that might affect its operation.

5. Forcing Components That Don't Fit Properly

Tool misuse frequently involves forcing parts together when they resist proper assembly. Hands that don't sit correctly, case backs that won't close, or movements that don't fit properly in cases all indicate underlying problems requiring investigation.

Forcing components creates stress fractures, bent parts, and alignment issues that affect long-term reliability. How to remove links from watches demonstrates proper techniques that don't require excessive force.

Quality components should fit together smoothly when properly aligned. Resistance usually indicates incorrect assembly procedures, wrong parts, or contamination preventing proper engagement between mating surfaces.

How to Avoid This

Stop immediately when components resist assembly. Investigate causes rather than applying more force. Check alignment, cleanliness, and proper part selection before proceeding with assembly procedures.

Use appropriate assembly techniques learned through practice and study. Beginning watchmaking requires patience and methodical approaches rather than brute force applications.

6. Attempting Complex Repairs Without Proper Knowledge

Watch tool mistakes escalate when attempting repairs beyond current skill levels. Complex procedures like gear train servicing, mainspring replacement, or escapement adjustment require extensive knowledge and specialized tools not found in basic kits.

Watch collecting for beginners emphasizes starting with simple maintenance tasks before progressing to complex internal repairs that can permanently damage valuable timepieces.

Understanding what is a hacking movement helps determine which repairs are appropriate for different skill levels. Some adjustments require specialized knowledge that takes years to develop properly.

How to Avoid This

Start with simple tasks like strap replacement and basic cleaning. Progress gradually to more complex procedures as knowledge and confidence increase through practice and study.

Use DIY watchmaking kits designed for your skill level. These kits provide appropriate challenges without overwhelming beginners with procedures beyond their current capabilities.

7. Neglecting Safety and Organization

Repair errors often result from poor organization and inadequate safety precautions. Small parts get lost, tools become damaged, and components suffer contamination when workspaces lack proper organization and safety protocols.

Proper storage methods protect both tools and timepieces from damage during extended storage periods. Organization prevents loss of critical components that might be impossible to replace later.

Safety precautions protect both the repairer and the timepiece. Sharp tools, delicate components, and precision adjustments all require careful handling to prevent injury and component damage during repair procedures.

How to Avoid This

Maintain organized workspaces with proper storage for tools and components. Use appropriate safety equipment including gloves, eye protection, and proper lighting for detailed work.

Develop systematic approaches to disassembly and assembly. Document procedures and component placement to ensure successful reassembly of complex mechanisms without missing critical steps or components.

Build Right with Rotate Watches

Time isn't just measured, it's built with your own hands.

Start your watchmaking journey with Rotate Watches, where complete DIY kits transform curiosity into craftsmanship.

Browse our collection to find your perfect match, from complete watch kits to intricate movement kits.

Your watchmaking story begins with avoiding these common mistakes. Start building today.

FAQ

Q. What are the most common watch tool mistakes beginners make?

Beginners often over-tighten screws, use household tools instead of proper watchmaking instruments, and attempt complex repairs without adequate knowledge. Starting with basic watchmaking kits and proper instruction prevents most costly mistakes.

Q. How can I avoid repair errors when working on mechanical movements?

Study your specific movement type thoroughly before beginning work. Use proper tools, maintain clean workspaces, and never force components that resist assembly. Movement-specific guides provide essential information for safe repair procedures.

Q. What essential tools prevent tool misuse in watch repair?

Quality screwdrivers, case opening tools, hand pullers, and cleaning supplies form the foundation of proper watch repair. Complete tool sets include everything needed for basic maintenance without improvising with inappropriate substitutes.

Q. When should I seek help instead of attempting DIY repairs?

Complex internal repairs, timing adjustments, and valuable vintage timepieces require specialized knowledge and tools. Start with simple procedures and progress gradually as skills develop through practice and study.

Q. How do watchmaker tips help prevent common mistakes?

Professional techniques emphasize patience, proper preparation, and methodical approaches. Understanding how long automatic watches last and proper maintenance schedules prevents many problems before they require repair intervention.

Q. What maintenance practices prevent the need for frequent repairs?

Regular cleaning, proper storage, gentle handling, and appropriate winding techniques maintain timepiece health. Watch winders keep automatic movements properly lubricated while proper strap care prevents case damage from strap failures.