Article: Machine-Made vs. Hand-Assembled Watch Movements: Key Differences

Machine-Made vs. Hand-Assembled Watch Movements: Key Differences

60-Second Summary

Machine-made movements dominate modern watchmaking through automated precision manufacturing, while hand-assembled movements represent traditional craftsmanship with artisanal attention to detail. Machine production offers consistent quality, lower cost, and reliable precision, making timepieces accessible to more enthusiasts. Hand-assembled approaches prioritize individual character, customization potential, and heritage techniques. Modern DIY watchmaking bridges both worlds, allowing enthusiasts to experience hand-assembled craftsmanship while using quality machine-made movement components. Understanding these differences helps you choose between mass-produced reliability and personalized horological artistry based on your priorities, budget, and desired connection to traditional watchmaking methods.

Machine-Made Movement Production Methods and Approaches

Modern machine-made movements rely on computer-controlled manufacturing systems that produce components with microscopic precision. Automated machinery cuts gears, shapes springs, and assembles basic movement structures without human intervention.

Swiss manufacturers like those producing Seiko movements have perfected these automated processes. CNC machines create identical parts across thousands of units, ensuring each component meets exact specifications.

Hand-assembled movements take a completely different approach. Skilled artisans manually position each component, adjust timing mechanisms, and fine-tune performance characteristics. This process requires years of training and intimate knowledge of mechanical interactions.

The beauty of hand-assembled work lies in human judgment. While machines follow programmed instructions, experienced assemblers can detect subtle variations and make real-time adjustments that enhance performance.

Materials and Sourcing Strategies for Machine-Made and Hand-AssembledTimepieces

Machine-made movement production uses standardized materials sourced in bulk quantities. Steel alloys, brass components, and synthetic lubricants undergo rigorous quality control before entering automated assembly lines.

Cost efficiency drives material selection in machine production. Manufacturers choose materials that balance durability, performance, and affordability. Japanese movements exemplify this approach, delivering excellent value through smart material choices.

Hand-assembled movements often incorporate premium materials selected for specific characteristics. Artisans might choose particular steel grades for their working properties or select jewels based on individual movement requirements.

Craftsmanship traditions influence material selection in hand-assembled work. Some manufacturers maintain relationships with specialty suppliers who provide materials unavailable to mass producers.

Time Investment and Detail Focus in Hand-Assembled vs Machine-MadeProduction

Machine-made movements achieve remarkable efficiency through automated processes. Modern production lines can complete movement assembly in minutes, allowing manufacturers to meet global demand while maintaining consistent quality standards.

Precision in machine production comes from eliminating human variables. Automated systems repeat identical actions thousands of times, creating movements with minimal variation between units. This consistency makes machine-made movements ideal for everyday timepieces.

Hand-assembled movements require significantly more time investment. Skilled artisans spend hours on individual movements, carefully adjusting each component and testing performance throughout the assembly process.

The extended time investment in hand-assembled work allows for attention to details impossible in machine production. Assemblers can optimize individual movements, creating timepieces with unique performance characteristics.

Customization and Personalization Options in Hand-Assembled Craftsmanship

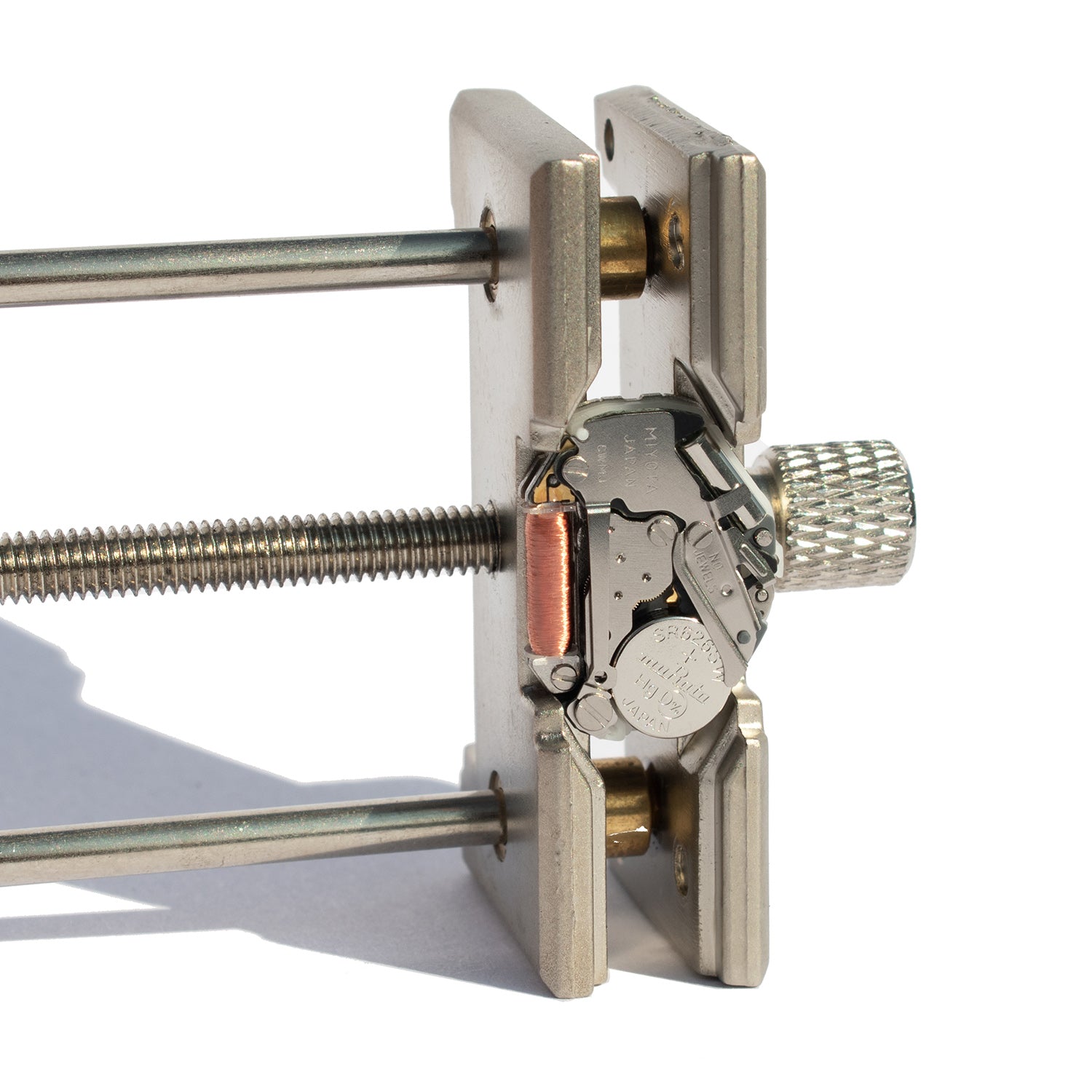

Machine-made movements offer limited customization options due to standardized production processes. However, modern DIY approaches allow enthusiasts to experience personalization through kits like the Seiko NH36 Movement Kit.

Hand-assembled movements excel in customization potential. Skilled assemblers can modify timing rates, adjust power reserves, and fine-tune performance characteristics to meet specific requirements.

Craftsmanship in hand-assembly extends beyond basic functionality. Artisans can add decorative elements, custom engravings, or unique finishing touches that reflect individual preferences.

Modern watchmaking kits bridge this gap by offering customization within structured frameworks. Products like the Marco Watchmaking Kit provide hand-assembled experiences while maintaining quality standards.

Brand Stories and Heritage in Machine-Made vs Hand-AssembledMovements

Machine-made movements often emphasize technological advancement and reliability. Brands highlight precision, consistency, and innovative manufacturing processes as key value propositions.

Hand-assembled movements leverage heritage storytelling and traditional craftsmanship narratives. These movements connect owners to centuries of horological tradition through individual artisan involvement.

The rise of DIY watchmaking creates new heritage stories. Enthusiasts building their own timepieces with kits like the Wright Watchmaking Kit develop personal connections to hand-assembled craftsmanship.

Cost considerations shape brand positioning in both categories. Machine-made movements enable accessible luxury, while hand-assembled pieces command premium pricing through exclusivity and individual attention.

Design Philosophy and Uniqueness in Hand-Assembled vs Machine-MadeApproaches

Machine-made movement design prioritizes efficiency, reliability, and cost-effectiveness. Engineers optimize layouts for automated assembly while maintaining performance standards across large production runs.

Hand-assembled movements embrace design complexity and artistic expression. Skilled artisans can accommodate intricate layouts, decorative elements, and unique complications that challenge automated systems.

Precision in design takes different forms. Machine production achieves precision through exact repeatability, while hand-assembly achieves precision through skilled adjustment and individual optimization.

Understanding mechanical watch basics helps appreciate these philosophical differences. Both approaches serve important roles in modern horology.

Manufacturing Characteristics of Machine-Made Movement Production

Machine-made movements benefit from advanced manufacturing technologies that deliver consistent quality at scale. Automated systems eliminate human error while maintaining tight tolerances across millions of components.

Quality control in machine production relies on statistical sampling and automated testing. Every movement undergoes identical procedures, ensuring performance standards meet specifications before leaving the factory.

Cost advantages in machine production come from economies of scale. High-volume manufacturing reduces per-unit costs, making quality movements accessible to broader audiences.

Modern Japanese mechanical movements demonstrate how machine production can achieve exceptional reliability and precision at competitive prices.

Handcrafted Production Features in Hand-Assembled Movements

Hand-assembled movements showcase individual artisan skills through careful attention to detail. Each movement receives personal attention, allowing skilled assemblers to optimize performance characteristics.

Craftsmanship in hand-assembly extends beyond basic functionality. Artisans can add finishing touches, decorative elements, and personalized adjustments that reflect individual expertise and attention to detail.

Quality control in hand-assembled work relies on artisan experience and individual testing. Skilled assemblers can detect subtle variations and make adjustments that automated systems might miss.

Precision in hand-assembly comes from human judgment and experience. Artisans can fine-tune individual movements to achieve optimal performance characteristics through careful adjustment and testing.

Mass-Production Advantages in Machine-Made Movements

Machine-made movement production enables consistent availability and predictable performance. Manufacturers can meet global demand while maintaining quality standards through automated processes.

Cost efficiency in mass production makes quality movements accessible to enthusiasts at various price points. Economies of scale reduce manufacturing costs without compromising essential performance characteristics.

Standardization in machine production ensures replacement parts availability and service support. Machine-made movements benefit from established supply chains and technical documentation.

Precision in mass production comes from eliminating variables through automated processes. Consistent manufacturing procedures create movements with predictable performance characteristics across entire production runs.

Quality Standards and Consistency in Hand-Assembled vs Machine-MadeProduction

Machine-made movements achieve consistency through automated processes that eliminate human variables. Quality control systems ensure each movement meets identical standards before leaving the factory.

Hand-assembled movements achieve quality through skilled artisan attention and individual testing. While variation exists between units, skilled assemblers can optimize individual movements beyond machine capabilities.

Precision standards differ between approaches. Machine production achieves precision through exact repeatability, while hand-assembly achieves precision through skilled adjustment and individual optimization.

Modern DIY approaches combine both advantages. Kits like the Seiko NH36 Movement Kit use quality machine-made movement components while providing hand-assembled experiences.

Application Across Luxury Categories

Machine-made movements serve various market segments, from entry-level timepieces to luxury watches. Advanced manufacturing enables complex complications at accessible price points.

Hand-assembled movements typically target premium segments where craftsmanship and individual attention justify higher costs. These movements appeal to collectors who value artisanal involvement.

Cost considerations influence application across categories. Machine-made movements enable luxury features at accessible prices, while hand-assembled pieces command premium pricing through exclusivity.

The growing DIY market creates new applications for both approaches. Enthusiasts can experience hand-assembled craftsmanship while using quality machine-made movement components.

Watches and Timepieces

Machine-made movements dominate modern watch production, powering everything from everyday timepieces to luxury complications. Automated manufacturing enables consistent quality across diverse applications.

Hand-assembled movements find homes in artisanal timepieces, limited editions, and custom creations. These movements appeal to collectors who value individual attention and traditional craftsmanship.

Precision requirements vary across applications. Sports watches prioritize accuracy and reliability, while dress watches emphasize aesthetics and traditional appeal.

Understanding how long automatic watches last helps appreciate quality differences between production methods.

Jewelry and Accessories

Machine-made movement technology extends beyond watches into jewelry and decorative timepieces. Automated production enables intricate complications in compact formats.

Hand-assembled craftsmanship creates unique jewelry timepieces with personalized elements. Skilled artisans can integrate movements into custom designs that reflect individual preferences.

Cost considerations influence jewelry applications. Machine-made movements enable affordable luxury accessories, while hand-assembled pieces command premium pricing through exclusivity.

The intersection of technology and craftsmanship creates new possibilities in jewelry timepieces. Modern manufacturing enables complex mechanisms in beautiful, personalized settings.

Customer Experience and Service

Machine-made movements benefit from standardized service procedures and readily available replacement parts. Authorized service centers can perform routine maintenance using established protocols.

Hand-assembled movements often require specialized service from skilled technicians familiar with individual characteristics. While more complex, this service maintains the personal connection between owner and timepiece.

Cost factors influence long-term ownership experiences. Machine-made movements typically offer lower service costs through standardized procedures and part availability.

Modern DIY approaches provide unique customer experiences. Building your own timepiece with kits like the Hudson Watchmaking Kit creates personal connections to hand-assembled craftsmanship.

Choosing What Works for You

Machine-made movements suit enthusiasts who prioritize reliability, consistency, and value. These movements offer predictable performance and accessible pricing across various applications.

Hand-assembled movements appeal to collectors who value individual attention, traditional craftsmanship, and unique characteristics. These timepieces offer personal connections to horological heritage.

Cost considerations play crucial roles in decision-making. Machine-made movements provide excellent value through economies of scale, while hand-assembled pieces justify premium pricing through exclusivity.

Precision requirements vary among enthusiasts. Some prioritize absolute accuracy, while others value the character and uniqueness that comes from skilled hand-assembled craftsmanship.

The growing DIY market offers middle-ground solutions. Watchmaking kits provide hand-assembled experiences while using quality machine-made movement components, creating personalized timepieces at accessible prices.

Consider your priorities, budget, and desired connection to traditional watchmaking when choosing between machine-made and hand-assembled movements. Both approaches offer unique advantages and serve important roles in modern horology.

Time isn't just measured, it's built with your own hands.

Start your watchmaking journey with Rotate Watches, where complete DIY kits transform curiosity into craftsmanship.

Browse our collection to find your perfect match, from complete watch kits to intricate movement kits.

Your watchmaking story begins with a single screw. Start building today.

FAQ

Q. What makes hand-assembled movements more expensive than machine-made ones?

Hand-assembled movements require skilled artisans who spend hours on individual timepieces, while machine-made movements use automated processes that complete assembly in minutes. The time investment and specialized craftsmanship justify higher costs.

Q. Are machine-made movements less precise than hand-assembled ones?

Machine-made movements achieve precision through consistent automated processes, while hand-assembled movements achieve precision through skilled individual adjustment. Both can deliver excellent accuracy, but through different approaches.

Q. Can I build my own hand-assembled watch without professional training?

Yes, modern DIY kits like the Seiko NH36 Movement Kit provide hand-assembled experiences with detailed guides and quality components. These kits make traditional craftsmanship accessible to beginners.

Q. Which type of movement requires more maintenance over time?

Machine-made movements typically require less frequent maintenance due to standardized components and consistent manufacturing. Hand-assembled movements may need more specialized attention but often receive more thorough individual care.

Q. How can I tell if a watch has a machine-made or hand-assembled movement?

Look for finishing details, component variations, and manufacturer documentation. Hand-assembled movements often feature individual marks, custom elements, or unique characteristics that reflect artisan involvement.

Q. What's the best choice for someone starting their watch collection?

Machine-made movements offer excellent value and reliability for beginners, while DIY kits provide hand-assembled experiences at accessible prices. Consider your budget, interests, and desired connection to traditional craftsmanship when choosing.